CHARACTERISTICS / PACKAGE / PRODUCTIVE SYSTEM

ORIGIN:

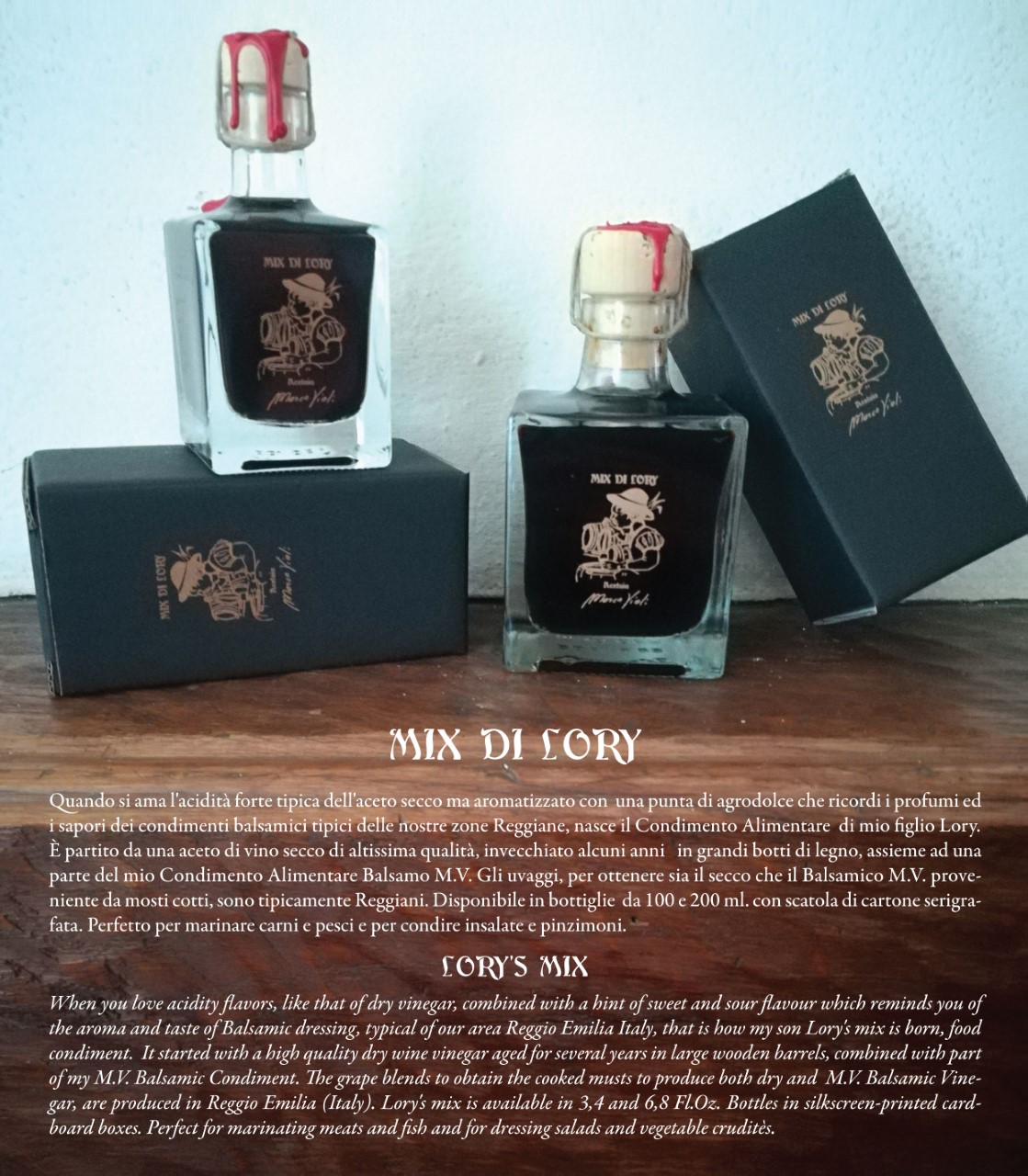

When you love the strong tart flavor of dry vinegar with the taste and aroma of Balsamic condiment typical of our region, Reggio Emilia, then we have just describedLory’s Food Dressing.

It is produced with high quality dry wine vinegar combined with “Balsamic M.V”. condiment and aged for several years in large wooden barrels.

The cut is then refined for a year in oak and chestnut barrels until a homogeneous and well blended product is obtained.

Our product is gluten-free with no added sulfites and no caramel, preservatives, colorings or artificial aromatic additives.

EXPIRY DATE:

The product does not expire.

STORAGE:

Our product comes in 100 ml. and 200 ml. (3.4 and 8.5 Fl. oz.) bottles.

The bottle has a wax sealed cork-like stopper and a screen-printed profile portrait of Lory designed by a friend, Carlo Dotti.

The bottle comes in a silkscreened cardboard box.

USE:

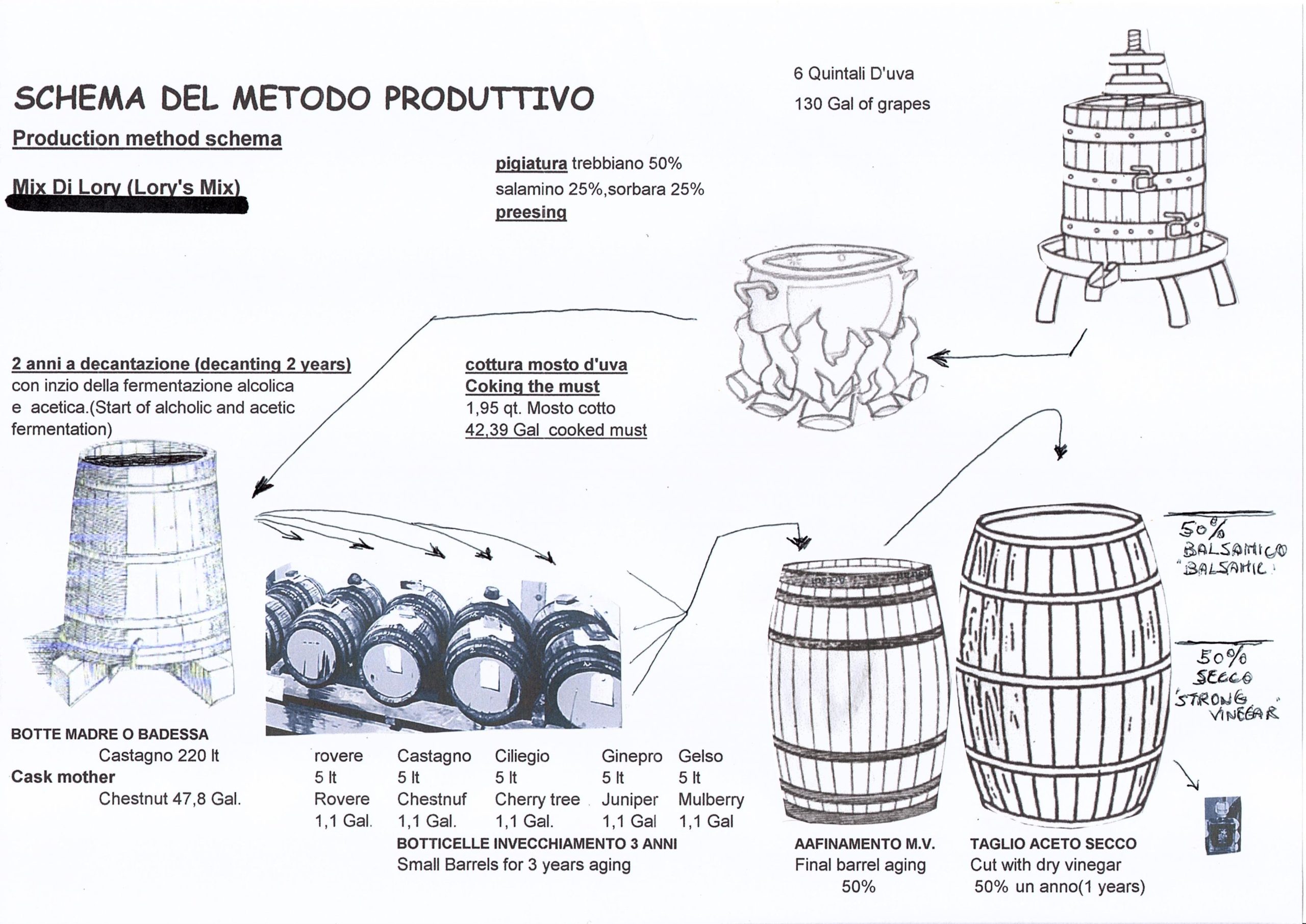

The procedure takes no less than 7 years for cooked grape must (“Balsamic M.V.”) and two years for wine vinegar, in a natural environment: hot in summer, cold in the winter.

The typical characteristics of processing this dressing consists in the aging of M.V. Balsamic condiment in small casks of various woods and the wine vinegar in larger barrels.

Balsamic Vinegar is refined over time thanks to the annual refilling or topping off with cooked grape must transferred from the “badessa” or “botte madre” (mother barrel) containing fermented cooked grape must acetified for two years.

After 6 years the product is ready.

Dried vinegar is aged in large oak barrels and will not undergo any special treatment until it is cut with the M.V. Balsamic Vinegar.

Grapes used:

“Lory’s Mix” is obtained from grapes grown in vineyards located in the province of Reggio Emilia.Marco Violi mainly uses white grapes.

MATURATION AND AGING of the “Balsamic M.V.” Condiment

used for Lory’s Mix:

The grape must is cooked over an open fire until it’s reduced approximately to a third

of its original volume.

It has two important purposes:

1. To sterilize the must from unwanted substances. Impurities are skimmed away

and discarded because it could alter fermentation which should take place only

in the barrel.

2. To reduce the grape must to a concentrate of about one third of its volume by

evaporation. Cooking induces a series of reactions, which mainly involve sugar

concentration that contribute to define color and part of the aroma that is

typical of balsamic vinegar. The sugar content also provides nourishment for

the yeast. Yeast transforms sugar intoalcohol, producing nourishment for acetic

bacteria which then turns the alcohol into acetic acid.

The grape must is simmered for about 12 hours. It is the manufacturer’s

responsibility to avoid excessively over cooking at high temperatures as the sugar

will caramelize, blocking fermentation, thus giving the must an unpleasant,

scorched taste.

Alcoholic fermentation and Acetic oxidation

To obtain a must with 24% sugar and 6% alcohol the cooked must is removed from

the kettle and cooled, then it is transferred to holding tanks “badessa” and combined

with an older Balsamic Vinegar that includes various active yeasts and bacteria which

help turn the juice into acetic acid (vinegar).

The cooked must actually benefits from the alternating cold winter season and the

summer heat.

The cold temperature allows the must to rest and mature; the grape must is decanted

and becomes a naturally clear color.

In the summer the vinegar bacteria are set in motion and transforms the alcohol of the

must into acetic acid.

During summer months the area should be ventilated and premises kept dark.

This natural chemistry allows Balsamic Vinegar to develop and improve for years.

3.Maturation and Aging in Wooden Casks

The fermented and acetified must in the “badessa” can now be transferred in small

casks of 5/6 liters each, where the vinegar goes through what is called “maturation”

and aging.

At this point it is fundamental the care and the attention in which the producers

choose the various types of wooden casks to use in the production of the Balsamic

Vinegar. Most producers use a variety of woods.

The woods generally used are:

• chestnut, which yields color and facilitates acidification;

• oak, strong and compact, confers a vanilla aroma;

• cherry, gives the condiment a fruit aroma, sweet and delicate;

• juniper, defines a strong aroma of resinous wood.

AGING AND REFINING PROCEDURE:

The method is as follows:

• 1st year: each barrel “badessa” is filled to 80% of their capacity with cooked

must for fermentation and acidification and it is left to rest for at least two years.

• 3rd year: the vinegar is decanted and transferred to the 5-liter casks for aging.

During this phase it is necessary to maintain the vinegar volume constant inside

every cask over the years by refilling or “topping up” or “topping off” with

other vinegar (each year the cooked must loses approximately 10% of its

volume through evaporation).

• 6th year: the finished product is withdrawn from the casks and put to rest and

refine in a large oak barrel.

• 7th / 8th year: the Balsamic Vinegar is ready.

CONTROL:

Chemical characteristics: each batch is controlled for density and acidity.

“Lory’s Mix” has a density of approximately 1,15/ml and about 9% of acidity.

Organoleptic characteristics: Before I consider the “Lory’s Mix” suitable for

bottling, each batch is examined for taste, visual characteristics and aroma.

INFORMAZIONI/VALORI NUTRIZIONALI

aggiornati per L.104061932-118111965-126092002

Mix di Lory

Valori Nutrizionali medi per 100 ml.

Avarage nutrition facts for 100 ml.

Valeurs nutritionelles moyennes puor 100 ml.

Nàhrwerte pro oder 100 ml.

Energia/Energy/Energie/Brennwert: Kj 1030-Kcal 242

Grassi totali / Total fat /Matières grasses/Fett: 0 g

di cui saturi/ Saturated fat/Dont acides gras

saturès/Davon gesàttigte Fettsàuren: 0g

Carboidrati totali/Glucides/

Total Carbohydrates:/ Kohlenhydrate: 56 g

di cui zuccheri/Sugar/Dont sucres/davon Zucker: 56 g

Fibre / Fiber/Fibres: 0 g

Sodio/Sodium/Natrium: 0,02 g

Proteine/Protein/Protèines/EiweiB: 1,2 g

Sale/Salt/Sel/Salz: 0,05 g

Informazioni generali per tutti i prodotti:

.-Fare attenzione alla data di scadenza;

.-Conservare a temperatura ambiente in luoghi asciutti

.-Dose giornaliera raccomandata (Reg. (UE) n° 1169/20119,

basato su una dieta di 2000 kcal/8400.

.-Il calcolo finale dell’energia è stato effettuato come previsto

dal regolamento (UE) n° 1169/2011 considerando

i valori medi di acidi organici.